Chemical/Electrical Building

Starting to set forms for the membrane building footing along the south wall line

Rebar and forming for the retaining walls of the Chemical/Electrical building

Stripping forms from the first retaining wall pour.

Rebar and forming for the retaining walls of the Chemical/Electrical building

Rough construction of access road north of the proposed membrane building site

Retaining wall west of the Chemical/Electrical building

Line feed pumps. The old soda system is being replaced with lime which will do a better job reducing hardness in the wastewater.

Retaining wall north of the proposed chemical/electrical building

Crew framing the retaining wall around the Chemical/Electrical Building.

Digging the footing for the retaining wall of the Chemical/Electrical Building.

Excavating footings for the retaining wall of the Chemical/Electrical Building.

Excavating footings for the retaining wall of the Chemical/Electrical Building.

Excavating footings for the retaining wall of the Chemical/Electrical Building.

Excavating footings for the retaining wall of the Chemical/Electrical Building.

Rebar and forming for the retaining walls of the Chemical/Electrical building.

Rebar and forming for the retaining walls of the Chemical/Electrical building.

Rebar and forming for the retaining walls of the Chemical/Electrical building.

Rebar and forming for the retaining walls of the Chemical/Electrical building.

Crews measuring elevation to determine depth for the footing of the Chemical/Electrical Building.

Pre-excavation of the floor for the building and wall of Chemical/Electrical Building.

Pre-excavation of the floor for the building and wall of Chemical/Electrical Building.

Keyway for the retaining wall and foundation of Chemical/Electrical building.

Keyway for the retaining wall and foundation of Chemical/Electrical building.

Outside wall of chemical electrical building

Progress on the Chemical/Electrical Building.

Retaining wall for the Electrical/Chemical Building

Working under the tarp to keep concrete curing at the right temperature

Work on pedestals during the snow. There will be sixteen 10î square tube columns and five 8î square tube columns to support the overhead bridge crane and roof.

Work on pedestals during the snow. There will be sixteen 10î square tube columns and five 8î square tube columns to support the overhead bridge crane and roof.

Work on pedestals during the snow. There will be sixteen 10î square tube columns and five 8î square tube columns to support the overhead bridge crane and roof.

Work on pedestals during the snow. There will be sixteen 10î square tube columns and five 8î square tube columns to support the overhead bridge crane and roof.

Crew installed metal plates onto the bolts to keep them in the exact location during concrete pour. Lg structural steel tube columns (10î & 8î square) will mount on the shown anchor bolts at the top of the pedestals at floor level, and support the overhead bridge crane and roof.

Work on pedestals during the snow. There will be sixteen 10î square tube columns and five 8î square tube columns to support the overhead bridge crane and roof.

Preparing for concrete pour for conduits. The form is a replica of what the transformer pad will look like. The distance from transformer to the electrical building is critical so the template ensures being exact.

Preparing for concrete pour for conduits. The form is a replica of what the transformer pad will look like. The distance from transformer to the electrical building is critical so the template ensures being exact.

Setting the new PG&E transformer

Inside for new transformer

Laying in the new electrical cable to the new transformer

Tying into the new transformer

Electrical conduits off the news transformer for the CE building

Tying rebar at the CE building

Tying rebar at the CE building

Framing for the concrete pour

Rebar for the CE building

Concrete form at CE building

Construction brick walls at Chemical/Electrical building

Construction brick walls at Chemical/Electrical building

Conduit at Chemical/Electrical Building

Removing forms at Chemical/Electrical Building

Conduit outside of the Chemical/Electrical Building

Conduits at Chemical/Electrical Building

Conduits that will be under the slab in the Chemical/Electrical Building

An intricate network of rebar at the Chemical/Electrical Building

Conduit outside of the Chemical/Electrical Building

Installing blocking and fascia at Chemical/Electrical Room

Electrical conduits from Electric Room to Zmod panel

Installing pre-plumbed chemical treatment systems

Holds chemical storage and new generators used in the event of a power outage.

Chemical tanks in the Chemical/Electrical Building

The view looking at the Chemical/Electrical Building.

New epoxy floor in CE Building at gen set

Standby generators tested with external load bank

Installing temporary alarm circuits for new generators in Chemical/Electrical building

Kodiak Roofing started work at the Chemical/Electrical Building.

WWTP engineers monitor and test chemical levels and effluent throughout the treatment process

Lugs switched at generator sets for phase rotation

Structural steel

Detail of roofing truss

Installing pan decking at CE building

Chemical/Electrical building with beams in place

Completed structural steel on Chemical/Electrical building before pan decking installation

Completed roof on Chemical/Electrical Building

Jeffco is shown here painting the door at the CEB. They painted all the doors on the site. SRC also installed safety signage throughout the site as shown.

ARV and vent piping from high points of UV system

The removal of existing propane standby generator at Chemical/Electrical building

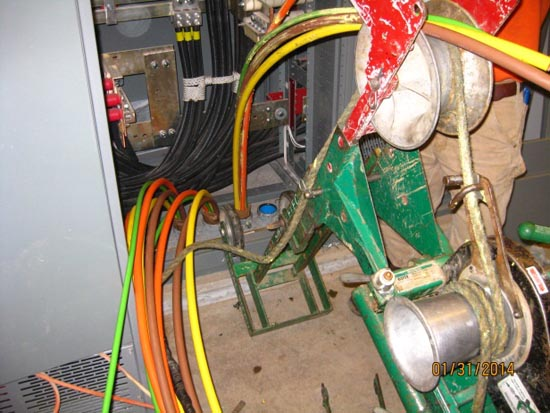

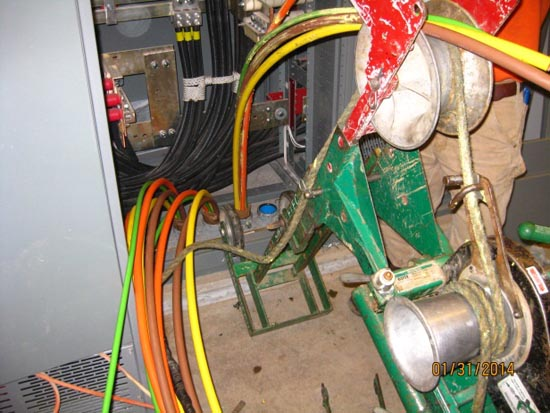

Pulling wire into auto transfer at Chemical Electrical Building

Protective temporary rail for electrical at UV system

The view looking at the Solids Tank and the west wall of the Chemical/Electrical Building.

Tanks1 Propane gas piping and heat exchanger makeup tanks

Air compressors, heat exchangers, and transfer pipes

Chemical/Electrical building

Installing insulation at Chemical/Electrical building

Support for drop ceiling at Chemical/Electrical building

Welding roof decking at Chemical/Electrical building

Lighting panels in interior of Chemical/Electrical building

Wiring from buss on left to both standby generators

Welding pipe support for the heat exchanger exhaust

Diesel fuel piping from exterior fuel tank to generator sets

The install of UV reactor piping with influent header to rear.

Pulling wire to Membrane Building at electrical room

Warming lights/blankets prior to pouring of concrete pads.

Wire pull for power to EQB from Chemical Electrical Building

Switchgear at Chemical Electrical building and breaker panel

Termination location of main feeders to buss bars

Heat exchangers and transfer pumps being tied-in.